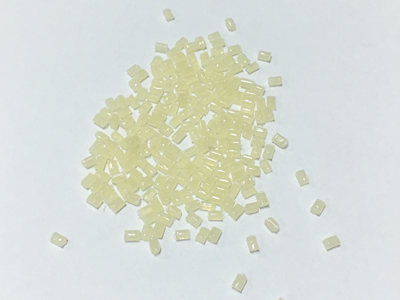

- 产品名称:奈米尼龙Ardlon-NE

- 简介:

Ardlon-NE奈米尼龙,独特性能如下:

高光泽高耐热性,远优于一般塑料材料

优良的电镀表面质量

成型加工良率高,降低成本

优异的油气阻隔性与耐冲击性

详细说明

两个产品分别为:NE2640、NE8088。

NE2640是一种奈米级尼龍工程塑料,具有高表面平整性、耐热性及耐冲击性,并能在成形收缩率、塑料流动性及尺寸安定性等多方面取得适当的平衡,适用于仿烤漆表面或车灯无底涂之产品。

特性 | 测试方法 Test Method | 单位 | NE2640 | |

| 耐冲电镀级 | ||||

| Plat. and Impact Grade | ||||

| DAM | 50%RH | |||

| 拉伸强度 | ASTM | Mpa | 80 | 70 |

| Tensile Strength | D-638 | |||

| 拉伸断裂伸长率 | ASTM | % | 3.1 | 3.9 |

| Tensile Strain at Break | D-638 | |||

| 弯曲强度 | ASTM | Mpa | 140 | 132 |

| Flexural Strength | D-790 | |||

| 弯曲模数 | ASTM | Mpa | 4125 | 3700 |

| Flexural Modulus | D-790 | |||

| 冲击强度IZOD,切角 | ASTM | J/M | 71 | 131 |

| IZOD Impact Strength, Notched | D-256 | 23℃ | ||

| 热变形温度 | ASTM | ℃ | 125 | - |

| Heat Deflection Temperature at 1.82Mpa | D-648 | 192 | - | |

| Heat Deflection Temperature at 0.45Mpa | ||||

| 软化点 | ASTM | ℃ | 212 | - |

| Vicat Softening Point(Rate B, Load 1) | D-1525 | |||

| 熔融指数 (230℃,5kgs) | ASTM | g/10min | 22 | - |

| Melt Flow Index at 230℃, 5kgs | D-1238 | - | - | |

| Melt Flow Index at 230℃, 2.16kgs | ||||

| 比重 | ASTM | g/cm3 | 1.15 | |

| Specific Gravity | D-792 | |||

| 熔点 | ASTM | ℃ | 225 | |

| Melting Point | D-789 | |||

| 吸水率 (50%RH,24hrs) | ASTM | % | 0.1 | |

| Water Absorption, 50%RH | D-570 | |||

| 吸水率 (浸于水中,24hrs) | ASTM | % | 0.7 | |

| Water Absorption, In Water | D-570 | |||

| 成形收缩率(流动方向) | ASTM | % | 0.5~0.8 | |

| Mold Shrinkage (MD) | D-955 | |||

NE8088I 为一高阻气性之奈米尼龙6复合材料。具有优异的油气外泄阻隔性及低温耐冲击强度,且具有高耐热性。

特性 | 测试方法 Test Method | 单位 Unit | NE8088I | |

| 高阻气、耐冲级 | ||||

| High barrier with super toughness | ||||

| DAM | 50%RH | |||

| 拉伸强度 | ASTM | Mpa | 50 | 47 |

| Tensile Strength | D-638 | |||

| 拉伸断裂伸长率 | ASTM | % | 150 | 210 |

| Tensile Strain at Break | D-638 | |||

| 弯曲强度 | ASTM | Mpa | 62 | 54 |

| Flexural Strength | D-790 | |||

| 弯曲模数 | ASTM | Mpa | 1600 | 1200 |

| Flexural Modulus | D-790 | |||

| 冲击强度IZOD,切角 | ASTM | J/M | 900(23℃) | 1000 (23℃) |

| IZOD Impact Strength, Notched | D-256 | 23℃ | 750(-40℃) | 850 (-40℃) |

| 热变形温度 | ASTM | ℃ | 72 | - |

| Heat Deflection Temperature at 1.82Mpa | D-648 | 171 | - | |

| Heat Deflection Temperature at 0.45Mpa | ||||

| 熔融指数 (230℃,5kgs) | ASTM | g/10min | 2.7 | |

| Melt Flow Index at 230℃, 5kgs | D-1238 | |||

| 比重 | ASTM | g/cm3 | 1.04 | |

| Specific Gravity | D-792 | |||

| 熔点 | ASTM | ℃ | 221 | |

| Melting Point | D-789 | |||

| 吸水率 (50%RH,24hrs) | ASTM | % | 0.18 | |

| Water Absorption, 50%RH | D-570 | |||

| 吸水率 (浸于水中,24hrs) | ASTM | % | 0.9 | |

| Water Absorption, In Water | D-570 | |||

| 成形收缩率(流动方向) | ASTM | % | 1.3~1.6 | |

| Mold Shrinkage (MD) | D-955 | |||

微特云办公系统

微特云办公系统